Predective engineering analytics(PEA)

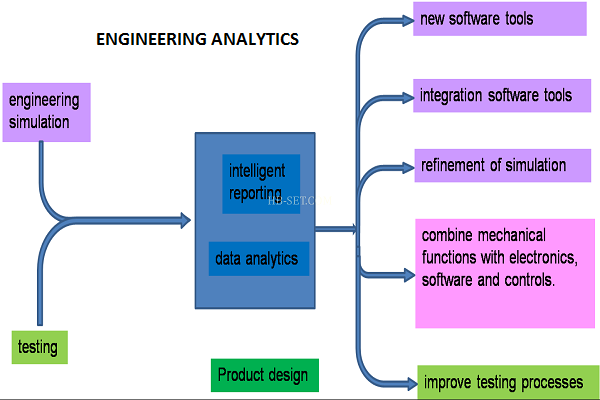

It is the application of multidisciplinary engineering simulation and test with intelligent reporting and data analytics for the manufacturing industry that helps to design complex products

It concerns the introduction of new software tools, the integration between those, and a refinement of simulation and testing processes to improve collaboration between analysis teams that handle different applications.

The objective is to let simulation drive the design, to predict product behavior rather than to react on issues which may arise, and to install a process that lets design continue after product delivery.

It is represents the next evolution of product development processes which currently rely on independent workflows in computer-aided engineering (CAE) and testing.

It addresses the complex nature of today’s products and product development environments, which combine mechanical functions with electronics, software and controls.

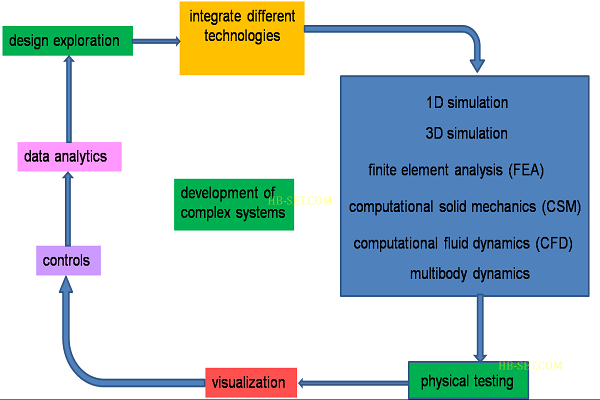

It integrates different technologies including 1D simulation, 3D simulation covering computational solid mechanics (CSM) and finite element analysis (FEA), computational fluid dynamics (CFD), and multibody dynamics, controls, physical testing, visualization, multidisciplinary design exploration, and data analytics in a managed context to support the engineering and development of complex systems.

It approach, the availability of sensor-based data combined with high-fidelity, physics-based simulations allows manufacturers to build and maintain digital twins of the product and to keep them in-sync with the product in use.